044 24960534, +91 8189929888, +91 8189941888, +91 9092929555

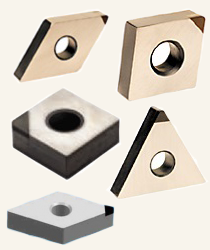

Product - PCBN Insert

PCBN - Polycrystalline Diamond Tools (Ferrous Metals)

| Machining Parameters - Recommended Machining Data for PCBN Tools | ||||

| Image | Recommended Material | Speed (SFM) | Feed Rate (IPR) | Depth of Cut (INCH) |

|

Pearlitic Gray Cast Iron |

600 - 1500 |

0.15 - 0.60 |

0.10 - 2.50 |

Tool Steels |

60 - 90 |

0.10 - 0.20 |

0.10 - 0.50 |

|

Hard Facing Alloys |

100 - 300 |

0.10 - 0.25 |

0.10 - 1.50 |

|

Finishing of Superalloys |

150 - 250 |

0.10 - 0.30 |

0.10 - 0.40 |

|

Hardened Steel ( >45 HRc ) |

65 - 120 |

0.10 - 0.50 |

0.50 - 2.50 |

|

Tool & Die Steels |

90 - 110 |

0.10 - 0.20 |

0.10 - 0.50 |

|

Hardened Steel Milling |

200 - 400 |

0.10 - 0.20 |

0.10 - 1.00 |

|

Features and Advantages

- PCBN inserts are compound super-hard material of polycrystalline cubic boron nitride layer and WC (Tungsten carbide) sintered under ultrahigh pressure and high temperature.

- The PCBN insert has the hardness, wear resistance and thermal stability of cubic boron nitride (CBN) and the shock-resistant toughness of hard alloy.

- By varying the binder phase and the percentage of CBN crystals, PCBN cutting tools can be made in a wide range of grades and in a variety of shapes and sizes for turning, boring, facing, forming, milling, grooving, reaming, parting, and fly cutting applications.

- PCBN cutting tools maintain their cutting edge, they impart excellent surface finishes to parts, while maintaining close tolerances and high productivity rates.

- We can manufacture the PCD/PCBN boring cutters of various specifications according to the need of our customers.

Longer tool life, Increased productivity, Uniform surface finish, High removal rate, Reduced machine down time, Cost effective.

Top