044 24960534, +91 8189929888, +91 8189941888, +91 9092929555

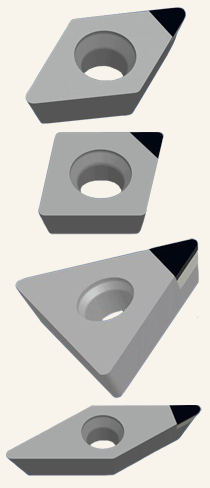

Product - PCD Insert

PCD - Polycrystalline Diamond Tools (Nonferrous Metals)

| Machining Parameters - Recommended Machining Data for PCD Tools | |||||

| Image | Material Machined | Operation | Speed (m/min) | Rate (mm/rev) | Feed DOC (mm) |

|

Aluminum Alloy 4 - 8% Si 9 - 14% Si >13% Si |

Turning Milling Turning Milling Turning Milling |

900 - 3500 1000 - 5000 600 - 2400 700 - 3000 300 - 700 400 - 900 |

0.1 - 0.4 0.1 - 0.3 mm ⁄ insert 0.1 - 0.4 0.1 - 0.3 mm ⁄ insert 0.1 - 0.4 0.1 - 0.3 mm ⁄ insert |

0.1 - 4.0 0.1 - 3.0 0.1 - 4.0 0.1 - 3.0 0.1 - 4.0 0.1 - 3.0 |

Metal Matrix Composites A1⁄10 - 20% SiC |

Turning ⁄ Milling |

300 - 600 |

0.1 - 0.4 |

0.2 - 15 |

|

Copper Alloys Copper, Zinc, Brass |

Turning ⁄ Milling Turning ⁄ Milling |

400 - 1260 400 - 1200 |

0.03 - 0.3 0.05 - 0.3 |

0.05 - 2.0 0.05 - 2.0 |

|

Tungsten Carbide (<16% Co1) Unsintered ("green") Sintered |

Turning Turning Turning Turning |

30 - 100 100 - 200 20 - 40 20 - 40 |

0.1 - 0.4 0.1 - 0.4 0.1 - 0.25 0.1 - 0.25 |

0.2 - 1.0 0.1 - 1.0 0.1 - 0.5 0.1 - 1.0 |

|

Ceramics Unsintered ("green") Sintered |

Turning Turning Turning |

70 - 100 70 - 200 50 - 80 |

0.1 - 0.4 0.1 - 0.4 0.1 - 0.25 |

0.2 - 1.0 0.1 - 1.0 0.1 - 0.5 |

|

Manufactured Woods |

Routing Sawing Routing / Sawing |

1000 - 3650 1500 - 4000 1000 - 4000 |

0.1 - 0.4 0.5 - 6.0 0.1 - 0.4 |

0.1 - 4.0 1.0 - 2.0 0.1 - 3.0 |

|

Plastics ⁄ Composites Carbon ⁄ Graphite Fiberglass ⁄ Plastics Fiberglass ⁄ Graphite |

Turning ⁄ Milling Turning ⁄ Milling Turning ⁄ Milling |

300 - 2000 200 - 1000 300 - 1000 |

0.05 - 0.3 0.05 - 0.5 0.1 - 0.4 |

0.1 - 3.0 0.1 - 3.0 0.1 - 3.0 |

|

Features and Advantages

- The PCD insert has the advantages of high abrasive resistance, high processing precision, good thermal conductivity and long service life.

- The cutting edge is sharp.

- The PCD insert can realize high speed cutting and hard material cutting with high work efficiency.

- The PCD insert can facilitate fast clamping.

- The PCD insert can be used repeatedly, which helps to lower your processing cost.

Longer tool life, Increased productivity, Uniform surface finish, High removal rate, Reduced machine down time, Cost effective.

Top