044 24960534, +91 8189929888, +91 8189941888, +91 9092929555

Product - PCD Reamer

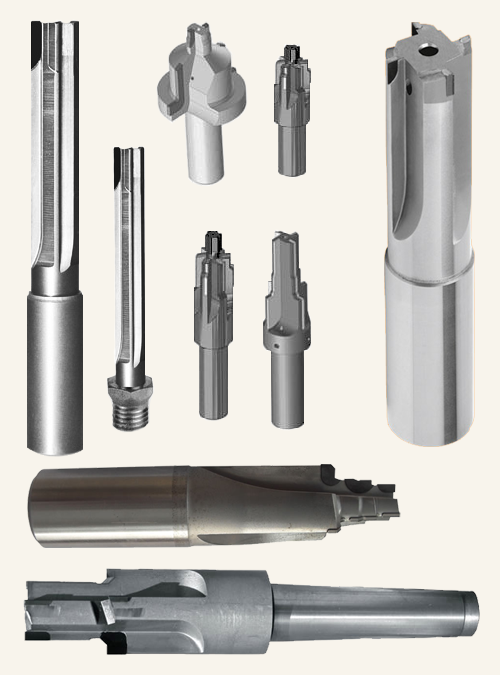

PCD Reamer

PCD (polycrystalline diamond) Reamers, Light-duty and high-tensile materials has begun to replace traditional materials such as cast iron or steel in the automotive and aerospace industry. For the economical, precision machining of sophisticated materials, PCD Reamers cutting tools are the right choice. This is because PCD Reamers cutting tools deliver users better quality, greater process reliability and, above all, increased productivity.

PCD Reamers has become the best Ultra-hard cutting material for machining non-ferrous metals and non-metallic component materials.

For lightweight and composite materials, PCD tipped reamers are being used increasingly for highly complex reaming operations. For the complete machining of reamed holes in aluminium, KHK Diamond Tools supplies special multiple-blade PCD-tipped reamers.

PCD Reamers tools used for high precision and close tolerance finishing of automotive engine parts, miniature parts, electronic parts and related products. PCD Reamers are excellent in large production runs due to its high resistant to wear and capacbility to machine at high speed.

PCD Reamers tools also used in particular for machining aluminium components such as brake pumps, cylinder head valve parent bores, injection bores, gear box housing, transmission casings and steering-system tubes among many other application for the automotive industry.

The precise manufacturing methods of PCD Reamers tools used for making PCD reamers are capable of achieving low run values below 4 ?m and operating speeds in excess of 10,000 min-1. If requested. In addition, our reamers can also be supplied completely assembled and fine-balanced with our radial/axial compensation holder, so that the setting-up time is minimized and machines can be rapidly equipped with the necessary tools without delays.

Features and Advantages

- The PCD Reamers has Significantly higher cutting speeds and feed rates.

- Increased dimensional accuracy and process reliability.

- Less process steps which means extensive freedom from burr

- The PCD Reamers can facilitate fast clamping.

- Ultra-long life of PCD tools.

- Less tool changes which means combination of multiple operations in one tool deliver savings on machine costs.

- Tool costs reduced by up to 50 % which means regrinding and reconditioning.